Modern design software available at the Faculty of Architecture greatly supports students in their projects, saves time and produces spectacular results. Every architect is also an artist to some degree, and mastering the noble art of freehand drawing is an essential part of their early education. As befits a 21st-century technical university, the Faculty’s Augmented Reality Lab has produced its first full-scale 3D-printed figure of a naked man – a faithful replica of a classical sculpture from a museum in Florence.

– Thanks to the model’s stability, we will be able to move it around and use it in various rooms – explains Bartosz Śliwecki PhD, Eng. Arch. from the Faculty of Architecture. – Unlike a human model, who may get tired or cold, this one won’t need a break.

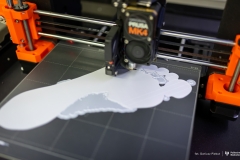

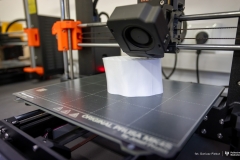

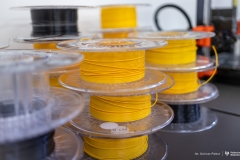

The creation of the model was made possible thanks to open-access 3D scans shared by technology enthusiasts. But having a digital representation of the sculpture was only the beginning. The 180 cm tall figure had to be divided into smaller segments and equipped with an internal structure to support the outer form. Material usage was also important, particularly the amount of 3D printing filament used. In this, Śliwecki was assisted by an intern from Gaziantep University in Türkiye, who had previously spent time in Białystok as part of the Erasmus+ programme.

3D Printing Requires a Plan

– During my first classes here, I was able to scan and print a figurine from my favourite video game, and that’s when I fell in love with 3D printing – recalls Tarik Avcu Nusret. Three years later, he returned to complete an internship at Bialystok University of Technology, focusing on 3D printing technologies.

– This human model is the largest 3D print ever produced at the University – says Tarik proudly. – My job was to ensure proper print time and structural stability of the final figure.

That was no easy task. Due to printer size limitations, the figure had to be divided into segments. The internal mesh structure also had to be optimised so the model would be both lightweight and stable once assembled.

– Printing this figure took about three weeks – says Tarik. – The 180 cm statue used about 10 kilograms of filament, and the finished model weighs just as much. It will be easy to move around.

The work at the AuReLa – Augmented Reality Lab is being closely followed by members of the Interdepartmental Student Research Group CAVE, based at the Faculty of Architecture.

– We’re currently creating a prototype scale model of Białystok at 1:1000 – says Inka Dziok, the group’s president. – We plan to make it accessible for people with visual impairments or those using wheelchairs. The AuReLa lab gives us tools to improve the quality of our models and enhance our education. For the first time, we can observe a large-scale 3D printing project unfold in real time.

The Challenges of 3D Printing

This is just the beginning. The team is already thinking about the next steps.

– Our goal is to design the models in a way that reduces the number of printed parts and increases the overall stability and visual integrity of the final product – explains intern Tarik Avcu Nusret.

The Faculty of Architecture does not plan to stop here.

– We are looking for more human figures – seated ones, less sculpted ones – really, we’re looking for 3D scans of human bodies that are less idealised than our classical print – says Śliwecki. – Natural human forms, with all their imperfections, are more valuable teaching models than flawless statues – and many professors of fine arts or design would agree.

The work carried out at the AuReLa – Augmented Reality Lab is a result of the union of art and technology.

– We heard from students that it would be helpful to have human body parts to study for drawing, and since we have the capacity to support education with high-quality printed models, we focus on producing precisely the ones that meet the needs of the curriculum – summarises Śliwecki. – It’s about enhancing the University’s capabilities and improving the quality of education at Bialystok University of Technology.

by jd

Bartosz Śliwecki, PhD, Eng, Arch. – Faculty of Architecture, Bialystok University of Technology

- Assistant Professor at the Software Department

- Specialist in the use of Generative AI in architectural concept design and eye-tracking technologies

- scientific project investigator under the Miniatura 8 programme of the National Science Centre

- Active scientific collaborator with international partners, including Vilniaus Kolegija, Lithuania