Bialystok University of Technology co-owns the patent for oxide-fluoride titanium germanate glasses with luminescent properties that will allow construction of new fibre-optic radiation sources

07-09-2022

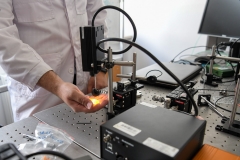

A fibre laser cutting human tissue bloodlessly? This will be made possible thanks to a joint invention of researchers of Bialystok University of Technology, University of Silesia in Katowice and AGH University of Science in Kraków. – We have a patent for the glass which can be used to produce optical fibres for fibre lasers cutting human tissue – rejoices Assoc. Prof. Marcin Kochanowicz, DSc, PhD, Eng, Head of the Department of Photonics, Electronics and Lighting Technology of Bialystok University of Technology. – The infrared radiation used for this purpose causes coagulation, which means that less blood will be shed.

The Polish Patent Office has just granted patent no. 240781 to the three aforementioned universities, which have jointly developed a globally unique invention – oxide-fluoride titanium germanate glasses with luminescent properties in the mid-infrared range and a method for obtaining them.

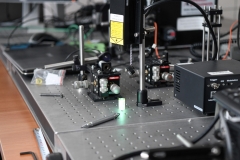

– These are special glasses that are doped with lanthanide ions with spectroscopic properties, applicable in the construction of fibre optic radiation sources, i.e. fibre lasers – explains Assoc. Prof. Marcin Kochanowicz, DSc, PhD, Eng, Head of the Department of Photonics, Electronics and Lighting Technology of Bialystok University of Technology. – The parameters of these glasses are different from the standard glasses we have known so far and allow us to obtain efficient emission – what is important – in the mid-infrared range, i.e. 2.70 micrometres – 3 micrometres. This range is of particular importance when it comes to medicine and optical sensors, since the whole photonic trend is shifting towards the infrared, because that is where the public needs applications.

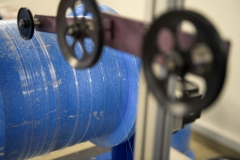

Oxide-fluoride titanium germanate glasses can be used in production of optical fibres.

– These optical fibres may be used to produce fibre lasers excellent for cutting human tissue wherever immediate coagulation is possible, and thus resulting in high precision – professor Kochanowicz briefly explains the practical application of the invention.

Such glass can also be used to study gas contamination.

– Every gas has certain absorption bands and where the emission of our glass overlaps – because these are active glasses, which are characterised by radiation emission – we can superimpose it on the gas absorption and in this way construct sensors that can detect gases polluting the atmosphere, such as ammonia – this is the spectral range – professor Kochanowicz explains.

He also reminds that optical fibre is an optical structure that propagates radiation by total internal reflection.

– It is not a tube – although there are also capillary optical fibres, but even a glass rod can be a simple optical fibre over a short distance – professor Kochanowicz explains.

The creators of the invention recorded in the patent description are Prof. Wojciech Pisarski, DSc, PhD of the Institute of Chemistry of University of Silesia in Katowice, Prof. Joanna Agnieszka Pisarska, DSc, PhD, Eng of the Faculty of Science and Technology of University of Silesia in Katowice, Assoc. Prof. Marcin Kochanowicz, DSc, PhD, Eng, Head of the Department of Photonics, Electronics and Lighting Technology of Bialystok University of Technology and Prof. Dominik Jacek Dorosz, DSc, PhD of the Faculty of Materials Science and Ceramics of AGH University of Science in Kraków. It took many years for the researchers to find the right glass composition.

– It required many hours of work, many tests, numerous compositions, and all of that in anaerobic conditions in special chambers, which gravely affected the speed of work – professor Kochanowicz explains. – We studied optical, thermal and structural properties of many compositions and selected the optimum glass in terms of optical and thermal properties, which allow it to be processed into optical fibres.

The researchers were predicting what dopants could make the glass useful for infrared radiation emission in the assumed wavelength.

– The know-how is not only my work, but that of the entire team and predecessors and in cooperation with University of Silesia responsible for manufacturing and optical measurements and with AGH University of Science that dealt with structural properties. Ready-made recipes for the right glass? No such thing. It’s years of research and background experience of predecessors. One could even say it’s a multi-generational work – reveals professor Kochanowicz.

The important thing is that titanium oxide – one of the main dopants – is available without problems.

Cooperation between University of Silesia, AGH University of Science and Bialystok University of Technology has been going on for years already.

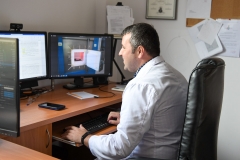

– We have joint scientific projects funded by the National Science Centre (NCN), we have scientist friends we met at conferences… Our cooperation is going perfectly, because we complement each other. We’re responsible for the optical fibres part, AGH University of Science – the structural part and the University of Silesia has excellent chemists who can design the glasses in cooperation with us. It’s working out perfectly – says professor Kochanowicz. – We are conducting interdisciplinary research from chemical technology through materials engineering, photonics in the broadest sense and the technology of optic fibres. It all has to work out, because we are not creating the material to study it and put it away, but to make it serve the society in one way or another.

The researchers dream of using their patented glass in production of optic fibres as a proposed source of radiation.

– Companies are interested in practical application of our inventions rather than in basic research, which is but the first step towards full success. First the glass, then the optical fibre and ultimately its real application – professor Kochanowicz reminds.

– We are always happy to have our research recognised. The patent is simply a confirmation of its novelty, quality and level. What we know for sure is that there was no such thing before and that is a step in science that will lead to practical solutions..

The researchers greatly value cooperation with students of Bialystok University of Technology.

– We also cooperate with our students, we attend conferences with them, they participate in our research, they are co-authors of publications, they are writing their engineering and master’s theses as parts of projects… – enumerates professor Kochanowicz. – We encourage our students to continue their studies at the doctoral school. It goes without saying – there is strength in young people.

About Assoc. Prof. Marcin Kochanowicz, DSc, PhD, Eng

- Head of the Department of Photonics, Electronics and Lighting Technology of Bialystok University of Technology

- expert and reviewer for the National Centre of Science (NCN)

- member of the Committee on Metrology and Research Equipment of the Polish Academy of Sciences (PAN)

- co-author of monographs and 86 JCR-listed articles

Description of the invention:

The aim of the authors of the present invention was to obtain oxide-fluoride titanium germanate glasses emitting intense radiation in the mid-infrared range.

The essence of the invention consists of oxide-fluorite titanium germanate glasses with luminescent properties in the mid-infrared range and of the following composition and reactant proportions: titanium oxide TiO2 in an amount from 5 to 55 mol %(preferably 40 mol %), germanium oxide GeO2 in an amount from 5 to 55 mol % (preferably 20 mol %), barium oxide BaO in an amount from 0 to 35 mol % (preferably 20 mol %), barium fluoride BaF2 in an amount up to 30 mol % (preferably 10 mol %), gallium oxide Ga2O2 in an amount from 4.5 to 19.5 mol % (preferably 9 mol %) and erbium fluoride ErF3 in an amount from 0.5 to 2 mol % (preferably 1 mol %).

The essence is also the method for the preparation of oxide-fluoride titanium germanate glasses with luminescent properties in the mid-infrared range, carried out in a chamber without air access, consisting in placing the crucible with the mixture of reactants in a furnace, where it is heated to 180 to 220°C and allowed to stand for at least 45 minutes, then melting the mixture at a temperature of 1150 to 1300°C in a continuous stream of inert gas and holding the mixture at that temperature for 45 to 90 minutes in order for it to homogenise, after which samples of glass are made by pouring the molten mass into a mould heated to the temperature of 275 to 325°C, and the thermal stresses in the samples are eliminated by annealing them in 275 to 325°C for at least 15 minutes. The synthesis is carried out with the following proportions of reactants: titanium oxide TiO2 in an amount from 5 to 55 mol %(preferably 40 mol %), germanium oxide GeO2 in an amount from 5 to 55 mol % (preferably 20 mol %), barium oxide BaO in an amount from 0 to 35 mol % (preferably 20 mol %), barium fluoride BaF2 in an amount up to 30 mol % (preferably 10 mol %), gallium oxide Ga2O3 in an amount from 4.5 to 19.5 mol % (preferably 9 mol %) and erbium fluoride ErF3 in an amount from 0.5 to 2 mol % (preferably 1 mol %).

Preferably, before placing the crucible with the reactant mixture in the furnace, the crucible is covered with a lid to reduce the volatility of the reactants.

Preferably, argon is used as the inert gas. Preferably, the samples are made in a brass mould.

As a result, transparent and completely amorphous pink-coloured materials emitting intense radiation in the mid-infrared range at a wavelength of 2.7 micrometres are obtained.

by jd