Forget it, let’s build a robot… An interview with Justyna Tołstoj-Sienkiewicz, PhD, Eng of the Faculty of Mechanical Engineering of BUT

08-06-2022

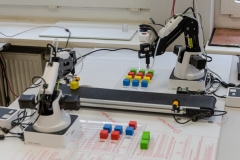

“Forget it, let’s build a robot” the enthusiasts of robotics associated with the Robotics Student Association at BUT say on their facebook page. It’s a group of students who share interests and an original way to enrich the time spent at the University. All of them, sooner or later, met Justyna Tołstoj-Sienkiewicz, PhD, Eng. It is she who was able to pass on the knowledge and passion for robotic construction creation while teaching students of automation and robotics, mechatronics and mechanical engineering. She’s been the supervisor of the Robotics Student Association for about 15 years.

How did your adventure with robots and the student association start?

I wanted to work with young people, so after graduating from automation and robotics, I decided to stay at the University and develop my career here. Not only in a scientific sense, but also in a didactic sense. I was attracted by that the most. At some point there was a group of young students interested in the robotics world. I went with them as their supervisor to Poznań to attend sumo robot competition. This trip sparked imagination and showed the students the possibility of creating something out of nothing. They liked the idea so much that they decided to found their own association at the Faculty of Mechanical Engineering. They started with Ryszard Szczebiot, PhD, as their supervisor, but when he left the University, they asked me to take over the association supervisor role. And that’s how it started…

We started from scratch, practically. At the beginning, the students were building robots using old parts that were no longer needed by other faculties. We made different and interesting attempts, which gradually brought us closer to building a sumo robot.

Before we come back to robots, let’s hear what robotics is about first.

It’s a field of science consisting of construction, use and development of machines that can work autonomously. These are devices that make our life easier by a lot. Robots aid us in work, but also in everyday life. Nowadays, we’re using robots more and more often and I think it’s the right direction.

So a cleaning robot belongs to robotics…

Of course!

… but a multi-functional coffee machine does not.

That’s an automaton. It is often difficult to tell automatons and robots apart, because they share many functions. Robots, however, can be reprogrammed at any time. You can change their tasks and purposes. Automatons, on the other hand, are systemised and operate in a continuous and defined way.

The robots that make vehicle body parts in a car factory, for example, operate in an automated way. They perform a repetitive action. However, we refer to them as industrial robots…

Indeed, because we can change their task at any time. They can be placed somewhere else and made to produce parts of chassis or even assemble car components if given another, fitting arm. The same robot could be capable of painting jugs. The difference is that industrial robots can perform many different tasks, while automatons are not so versatile.

Industrial robots are most often associated with a multi-tasking machine seated in place, but there are also machines that move…

These are specialised AGV-type (Automated Guided Vehicle) robots. Their task is to move objects logistically, they can, for example, palletise or organise cargo in a warehouse. We can update their path or movement range and define a new type of product at any moment. Such robots can move on different surfaces, move along and across walls, ceilings, racks – it all depends on a properly selected suspension system.

Not only are they mobile, they can also fight each other!

Their main task is to locate their opponent and push it out of the mat as quickly as possible. So, firstly, we equip the robot with sensors that will detect the white lines marking the area of fight. Secondly, we equip the robot with ploughs capable of lifting the opponent off the mat. Before that, however, they also have to be equipped with sensors detecting the presence of the opponent in order for the robot to detect them and launch the attack. There are numerous aspects worthy of consideration. Thanks to the experience our students gain by means of competitions, many interesting constructions, ideas and papers were created.

It has to be admitted that sumo robot fights are quite exhilarating not only for their constructors, but also for the audience. Their creation takes a lot of effort and time spent in workshops. They come out of fights in a pretty bad state, but it’s very satisfying to see them win.

I’m imagining another open days at the University with fights of robots equipped with flamethrowers… The audience would love it!

I think we can challenge the constructors. I’m sure they would not lack imagination and ideas, although my experience and caution suggest that it might not be a very good idea. [laugh]

How much time does it take to design and construct a sumo robot?

It takes at least a year to perfect a version that will fully satisfy us, meaning it works as intended and is capable of winning. This is because it needs to be thoroughly tested. It needs sparring with opponents, for example at competitions, and then improvements and corrections. It takes a lot of work and time. Year after year, students create better and better constructions drawing on experience and availability of better solutions and components. We are researching, modernising and upgrading things all the time. We also have better and better processors at our disposal, as well as sensors that react faster. This kind of upgrade is necessary, for “he who moves not forward, goes backward”.

Is this what the work of the Robotics Student Association looks like?

Our beginnings were humble. It was more than 10 years ago. At the time, 12-14 students were involved in robot construction. However, in just a few years, the association has grown to almost a hundred people. In terms of organisation and supporting students in development – as that was the very meaning of my work – it became increasingly difficult. I had to ask my colleagues for help. At this moment, there are three of us co-supervisors in the association – Assoc. Prof. Kazimierz Dzierżek, DSc, PhD, Eng and Rafał Grądzki, PhD, Eng. A colleague, Maciej Rećko, MSc, Eng is also helping us.

The association creates constructions of very different types. There were six-legged robots, four-legged robots, robots driving on Swedish Mecanum wheels, there were so called Line Followers, there was a whole series of Micromouse robots that seek the fastest way out of a labyrinth, as well as hybrid robots. In our association it’s the student that decides what they want to do or try. We’re trying our best to make it possible. We discuss the feasibility of projects or the need to modify it. We assess whether a student is capable of realising the project by themselves or whether they need a team. This is how it works, more or less. There have been hundreds of constructions since I have become the association supervisor. Sometimes I wonder where these young people get their ideas and knowledge from. I’m in awe. They’re capable of doing so much.

What encouraged the students to work as part of the association? There must be something else to it…

Achievements, possibilities of testing new things, access to better and better materials and tools, and above all – their curiosity! I think what contributed to the association’s success was what these young people are capable of, what they do in their free time and the very fact that the University allows them to do interesting things in a cool company. Later on, it was also the association’s popularity. It’s nice to be a part of an association that wins in competitions abroad. Thanks to the competitions we were able to travel to the United States, Australia, Japan and many European countries. We blazed a trail in an international competition of Mars rovers in the USA. We’ve participated in them since 2009! In 2011, the Magma2 rover won the first prize. Further successes followed in 2013 and 2014 with the Hyperion and Hyperion 2 rovers.

The association, however, starts with the basics. I encourage students who are at the beginning of their adventure with robotics, but are still undecided and don’t know what they’re capable of to construct robots using Lego sets. In the beginning, there were so called RCX, Mindstorm 2.0 and now we also have EV3. Lego constructions are versatile in a sense that they allow students to find out whether they want to be constructors, programmers or logistics managers.

Assuming we want to construct a robot…

First, we need to determine the task of the robot. Based on it, we determine its capabilities, the way it moves and what it should be able to detect. Then, how it should react to the retrieved information. That’s how what we should do next gets clarified. We choose core components and assemble them. We create a control algorithm and a programme that will attempt to realise the task, meaning we activate the drive, read the sensors’ status and based on it we realise one process or another.

So it’s the algorithm and computer programme that makes robots do their work in real time…

Indeed. This is what is beautiful about robots. They can, of course, operate on the basis of remote control. That’s their basic ability. But we are creating them so that they can operate autonomously when there is no one to control them or when control is not necessary. So that they can make decisions based on a certain range of information and programmes they’re equipped with.

And how does one construct a Mars or moon rover?

Definitely not quickly. [laugh] Bear in mind, that we are creating analogue rovers, meaning they will never go into space. They are, however, constructions full of students’ ideas. Hence the University Rover Challenge competition that we’re participating in. It’s held in order to find talented young people and incorporate their ideas into the space industry. It takes about half a year of intensive work of a team of 6 to 10 people for the idea to be realised. A team having a mechanical engineer, an electrical engineer, a programmer… In short: an efficient, harmonious team that would manage the construction of the robot, based on the analysis of previous designs, a lot of experience and achievements of our students and other teams, that would make decisions regarding chassis, engine, on-board system choice… And a bunch of other complex things that even I was troubled with at some point. All I had to do was make sure they had the capacity, funds and a sufficient supply of tea.

For real though, I admire these young people. Their abilities and knowledge. I’m aware that sometimes they can do much more than I can. It’s been fascinating to observe and support them in it and to see all the new things over the years.

What does the most prestigious competition – University Rover Challenge – look like?

The competition itself takes a few days. Before that, however, there are many months of preparation. First, of course, there are qualifications, then preparations for shipping the robot, as it’s shipped in parts secured in a box. Then there is the transport and the journey to the desert in Utah, where competition takes place. The terrain resembling Mars is located near the small city of Hanksville. This is where NASA Mars Desert Research Station is. Upon arrival, the competing teams assemble their rovers, especially the teams from abroad. It’s good if we have everything on us, but it has happened more than once for Polish teams to borrow tools from each other. Then we test the rovers, download the maps, GPS data and others and finally we go to the competition site. The rover is first checked to ensure it meets the weight limit – one of the most important criteria. Then the events are held in a way that there is actually almost no way to meet our opponents, as we are only allowed in the competition area during the competition task, which is about 30 minutes. Until the results are announced there is almost no way to know how the other teams did.

There are five events in the competition. Interestingly, every year the requirements are higher. I recall that during our first competitions, in the “finding life” event, it sufficed to take a soil sample, then carry out a few tests in the on-site laboratory and prepare a short lecture in which we assessed the possibility of the development of life based on the obtained data. In the next editions it was demanded that the soil samples be taken hermetically. Then it was demanded that a certain scope of testing be carried out on board of the rover before it returns to the base.

Thanks for taking time to meet with me. I wish you and your students every success at the next robotics competitions.

Krzysztof Sadowski, Radio Akadera

Justyna Tołstoj-Sienkiewicz, PhD, Eng

- lecturer at the Faculty of Mechanical Engineering of BUT (Department of Robotics and Mechatronics)

- specialist in the field of robotics

- supervisor of the Robotics Student Association since 2007